The Cargo Conundrum: Water Isn’t the Answer

Written By:

Trevor Pan, President BidBird, Inc.

The once $270 billion Panama Canal has become the Malt-O-Meal

of cargo transit. Along with its water levels, seaborne traffic has dropped nearly 40%.

For shipping companies, it’s understandable why the canal has fallen from the top shelf of the cereal aisle;

they can either cut in line (and pay to do it), or wait in line (and pay fines to their client).

Or, they can take an alternate, longer route (which, you guessed it, they pay for).

Why would anyone choose this unpredictable nightmare?

Cargo transshipment's don’t have a robust rail network to land on. After all, droughts of this kind are exceptionally

rare in a tropical locale. Furthermore, the oceans and cities adjacent to the ports make long rails impossible in Panama.

The last two-thirds of a train cannot get serviced, simply because the ports are not that long.

System for Cargo Transport

Filed with Patent Cooperation Treaty (PCT)

Patent application published

Began outreach to the Panama Canal Authority

Wall Street Journal Ad

Seeking investment bank to start process for issuing private corporate bonds

Preliminary design study

Coordinate an architectural and engineering study with canal

Photo: Panama Canal Authority

Photo: CBS News

Drought at Panama Canal Threatens 40% of Worldwide Cargo Ship Traffic (CBS News)

Photo: Martin Shields Director Business Development Shipping

Photo: Seattle Times Bloomberg

Saving the Panama Canal: Will Take Years and Cost Billions (The Seattle Times)

The Bundled Opportunity

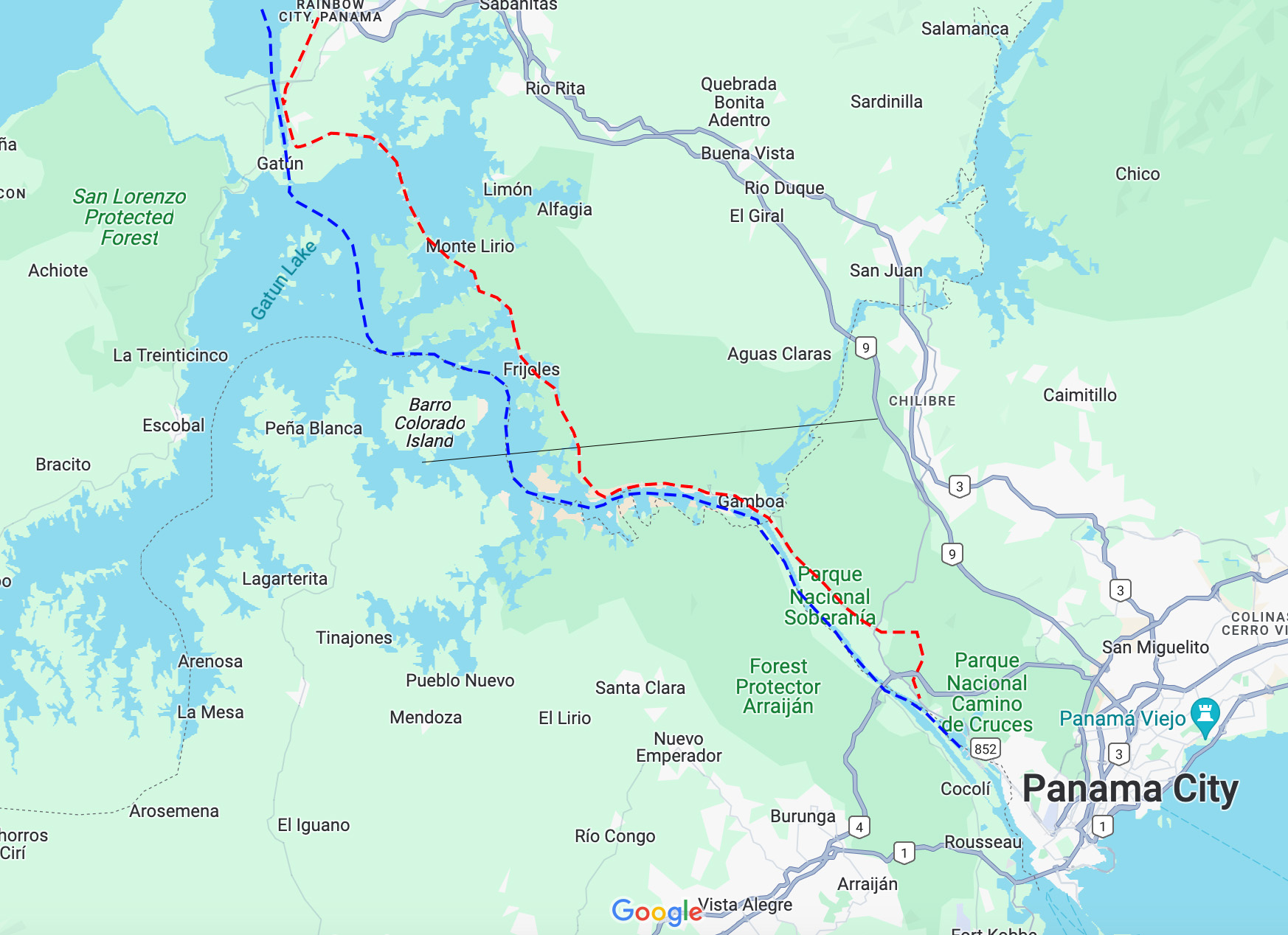

Our revolution of rail freight transshipment uses existing container terminals on both the Caribbean and Pacific sides of the canal.

The existing rail line that connects ports isn’t configured for major transshipments. But, it can be by either building a new two-pair rail project

or simply adding another pair of rails to move the bundles. Prior projects have already sketched this out.

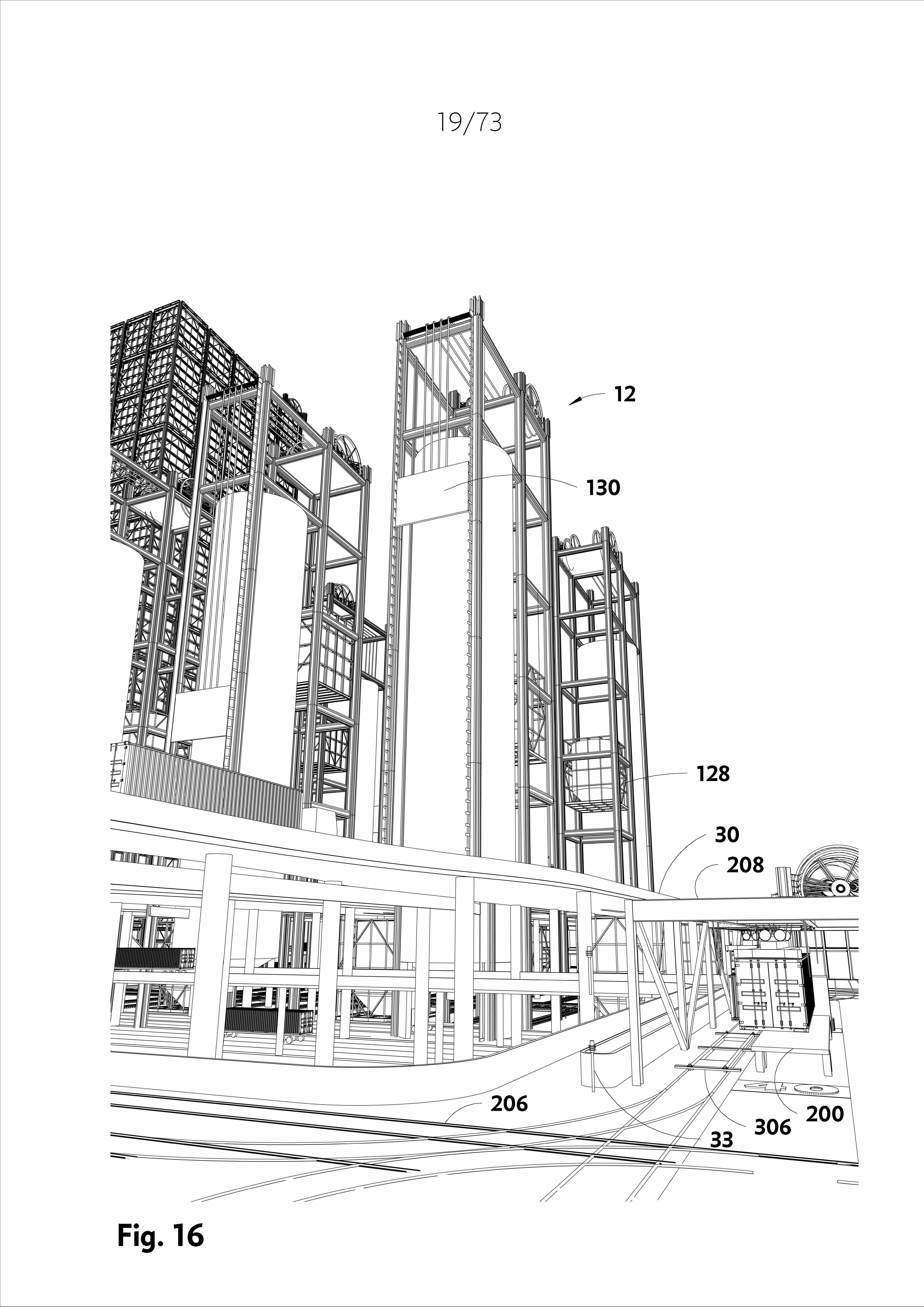

BidBird’s patent-pending bundle towers, as phase 2, make it possible for multiple liners to drop cargoes on one side, store them, then later

place them on a new liner on the opposite side of the canal. This changes the route of ships, but not of the cargoes inside.

Locations for container/cargo storage (and one prime spot) are shown in dashed red rectangle below.

In 2023, the Panama Canal traded $270 billion USD. Now, seaborne trade is down 30%.

Prospective Customers

The following ports would pay for the transshipment of cargoes and delivery to their terminal, shown below. With this, they can always depend on the rails to hold cargoes, whereas the canal is a wildcard.

Photo: Port terminals on the Caribbean Sea

Here are some of the locations of ports that this can be implemented in:

Photo: Port terminals on the Pacific Ocean

The BidBird Solution

The answer isn’t in the cereal aisle.

As drought conditions created these challenges for Gutan Lake — and subsequently for the operational

efficiency of the Panama Canal’s locks — our solution innovates alternative strategies without using water.

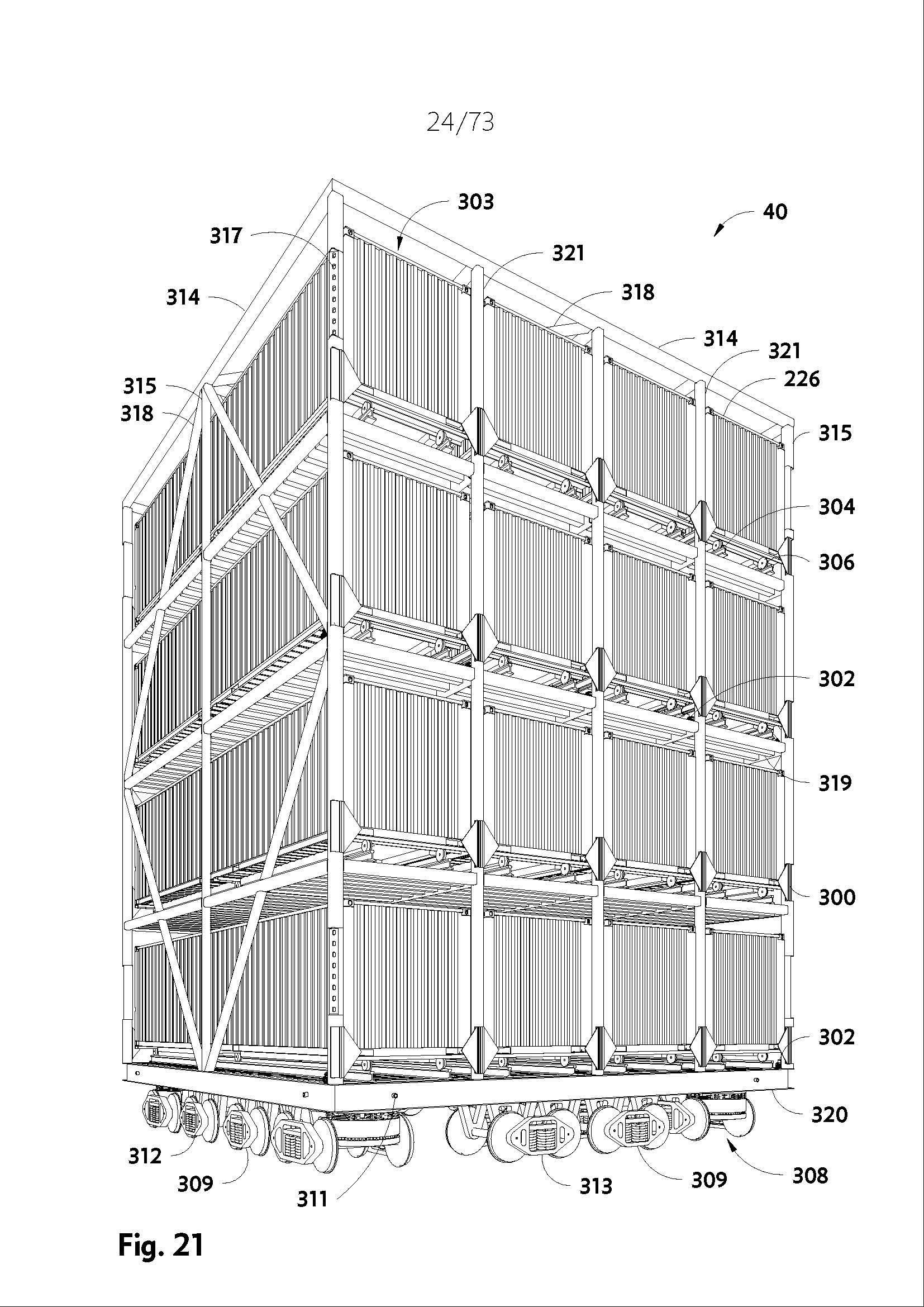

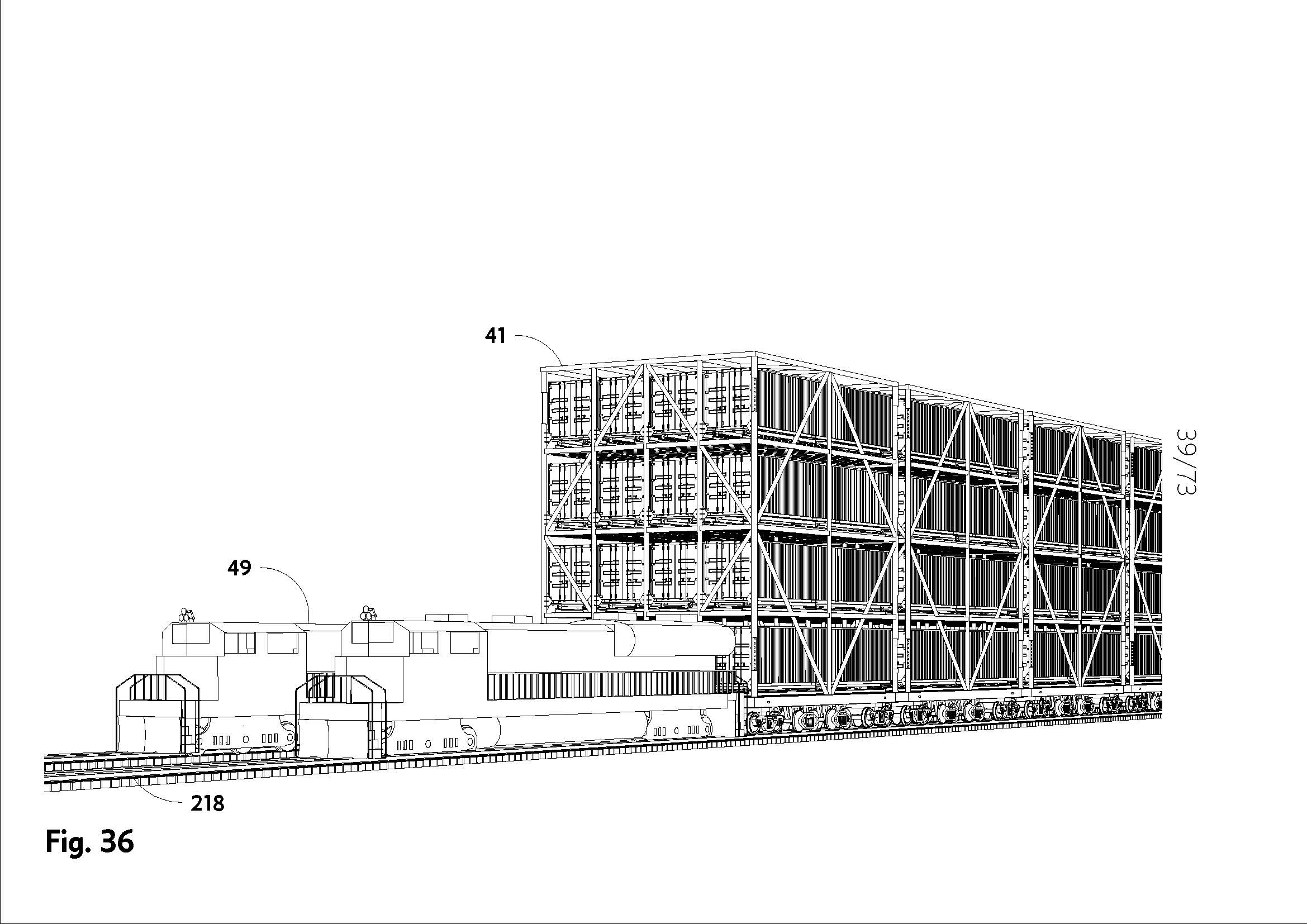

The patent-pending BidBird Bundle can deliver containers in densities never seen before. With 8x more space,

we can trim a mile long train to 1/8 of a mile, a two-mile train to 1/4 of a mile, and so on.

Overland transshipment now makes sense with the ability to move massive quantities of containers.

Rain or no rain, this year-round, predictable new method turns a costly problem into a no-brainer for container lines: drop off on the Pacific, and a new liner on the Caribbean picks up (and vice-versa).

Photo: PAN, Trevor Bundle (Above)

Photo: Possible rail spur/turnout and bundle tower site (Above)

Photo: Demonstrating this rail project will not interrupt canal traffic

(Above)Cost

50 miles of double track = 50 x $2,310,000 (low*) to $2,640,000 (high*)

Ballpark double track cost = $115,500,000 to $132,000,000

As can be seen below, strengthening a rail road track is also part of this patent.

The costs of adding steel, or creating a new rolling die at a steel plant with a

wider base flange are unknown. BidBird, however, has spared few details.

Photo: PAN, Trevor Strengthened Railroad Rail (Above)

An architectural / engineering study is required to determine how many turnouts are

needed to allow one train to continue while the opposing briefly steps aside. The

turnouts affect how many bundles would need to be welded/created. Also, local

authorities will need to weigh in.

This preliminary concept would likely run in the $250,000 to $500,000 range (quotes

from engineers will be needed). With this document, we can have a much more accurate

construction cost estimate. This estimate would be based on contractors licensed to

build in Panama.

There’s a bit of the unknown here; but, let’s say bundles are in the $25 million

range.

After this study, the investment bank can help estimate the operational costs needed

to service the bonds until the project begins to cash flow.

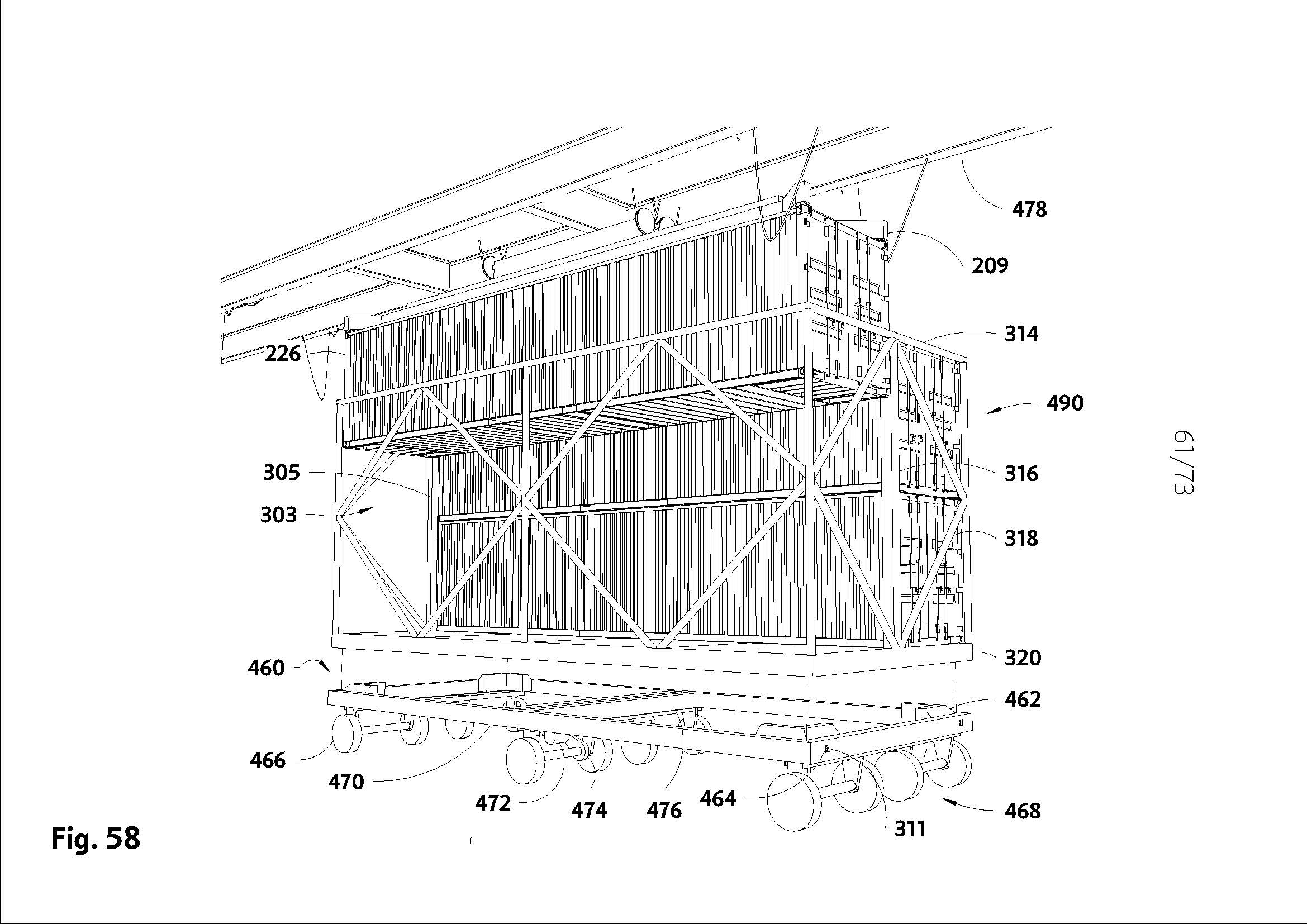

Below are several bundle concepts. One may board a BidBird Bundle Cargo Ship, and

traverse double tracks. The other is meant to be serviced by spreaders and gantry

cranes of existing port container terminals.

This option is attractive as rails will not likely be built up to gantry cranes; the

bundle having tires may traverse from the tracks over to and under existing gantry

cranes.

Mostly likely a combination of these will be used at Panama. Therein lies the

importance of the preliminary design study.

Photo: PAN, Trevor Bundle (Above)

Photo: PAN, Trevor Port Side Bundle Having Tires (Above)

Photo: PAN, Trevor Bundle Tower, Dry-Bulk Silo (Above)

Bond Repayment

Bonds will likely be repaid by the existing ports looking to transship the containers and other cargoes; there may also be cost sharing with the shipping lines. No matter the final arrangement, they’ll pay BidBird for the service of moving containers via land and not the canal itself.

Learn More

For additional insights into the economic impact of the Panama Canal and related infrastructure projects, explore the following resources:

- SYSTEM FOR CARGO TRANSPORT

- A system for cargo transport in the field of intermodal logistics aims to solve supply chain-related disruptions experienced during the Covid-19 pandemic.

Other Uses

The Panama Canal is not the only place these inventions can be put to use. Thailand, Turkey, Egypt, Mexico and even Israel are possible contenders.* For more information on railroad engineering construction cost benchmarks from a few years passed, visit Compass International.